Research is required to build any model correctly but we are all restricted by time and access to the information. This is true when you chose to build a model of something that did not exist in any substance and like all modelers an educated guess replaces hard data. Until the writing of the blog this is what had been done until a recent discussion with Ray Pilgram [Bylong]. Ray remembered a clinic that had was given on the Mary Vale to Golgong line at the Modelling the Railways in NSW Convention and that he would see if a copy of the presentation could be found. True to his word a PDF arrived via e-mail and the information forced a re think on the models design focus.

What was clear is that if the line had been build with the Golgong to Sandy Hollow line and the upgrade of the line from Sandy Hollow to Musslebrook the completed route would have become the main line of the system North to Newcastle especially for freight with it's superior grades. In the end what ultimately effected the decision was politics and the funding it attracted and that was the burden carried by the operators of the system. The NSWGR Railway's was not a business but a tool of its political masters.

What was clear is that if the line had been build with the Golgong to Sandy Hollow line and the upgrade of the line from Sandy Hollow to Musslebrook the completed route would have become the main line of the system North to Newcastle especially for freight with it's superior grades. In the end what ultimately effected the decision was politics and the funding it attracted and that was the burden carried by the operators of the system. The NSWGR Railway's was not a business but a tool of its political masters.

This posed problem's for the layout design assumption'. The effect was to move the focus from Spicers Creek to Drill Creek and from Melba Road to Goombla with a 1925 starting point assuming the track up grade from Sandy Hollow was not completed. This allow's running the trains originally discussed and avoiding the need to run C38, D57 and AD60 class locomotives which would be nearly impossible.

The article is reproduced and has been edited to focus on the Mary Vale to Golgong line:

The article is reproduced and has been edited to focus on the Mary Vale to Golgong line:

Presentation for:

Modeling the Railways of NSWGR Convention in 2003.

Sandy Hollow - Gulgong - Mary Vale

By Chris Wangmann

I would also like to say that a number of articles about the line have been produced over the years. I am in no way out to prove those articles to be incorrect, rather to say that this presentation is a result of my interest, research, inspections, operations and records.

HISTORY

The route of this line was originally surveyed in the 1855 to 1860 period. The Railway Surveyors are reported to have recommended that the main western line should follow approximately the same route as the Sandy Hollow to Mary Vale line from Newcastle for reasons of easier gradients over the Great Dividing Range. Political pressure of the day brought about the main western line being located where it is today. If it was constructed would provided a quicker route from Dubbo to Newcastle than could be achieved by traffic going via Werris Creek or Sydney.

The line then was initiated as a result of an investigation by a Royal Commission on decentralization of Rail Transport in 1911. It recommended a line be built from Mary Vale via Gulgong to Sandy Hollow, then to connect with the Muswellbrook to Merriwa branch line of the future. The Muswellbrook to Merriwa branch line was first passed by Act No: 11 of 1911. In1912 the first sod had been turned on the branch line and this was completed through to Denman on 25 May 1915. The Muswellbrook to Merriwa branch line opened fully on 29 October 1917. This would then connect the west of the state to a proposed new port to be built at Salamander Bay in Port. Stephens. The expenditure proposed for construction at Salamander Bay for shipping facilities, wharf lighting and dredging was to have been 600,000 pounds but was never constructed. The Mary Vale via Gulgong to Sandy Hollow was to be constructed as part of this decentralization.

The line then was initiated as a result of an investigation by a Royal Commission on decentralization of Rail Transport in 1911. It recommended a line be built from Mary Vale via Gulgong to Sandy Hollow, then to connect with the Muswellbrook to Merriwa branch line of the future. The Muswellbrook to Merriwa branch line was first passed by Act No: 11 of 1911. In1912 the first sod had been turned on the branch line and this was completed through to Denman on 25 May 1915. The Muswellbrook to Merriwa branch line opened fully on 29 October 1917. This would then connect the west of the state to a proposed new port to be built at Salamander Bay in Port. Stephens. The expenditure proposed for construction at Salamander Bay for shipping facilities, wharf lighting and dredging was to have been 600,000 pounds but was never constructed. The Mary Vale via Gulgong to Sandy Hollow was to be constructed as part of this decentralization.

An advantage of the Sandy Hollow-Mary Vale line was to be gained by providing an alternative route to the coastal and western areas of the state and a quicker route-to the North Coast. Although the proposed line would only be 122 miles shorter than the route from Dubbo to Newcastle via Sydney, it would have over 70 miles of easier gradients. The Sandy Hollow to Mary Vale line would provide the easiest crossing of the Blue Mountains from the West. It would have 1:80 grades in the Up direction and 1:50 grades on the down direction versus 1:30/40/44 on the main line from Dubbo to Sydney and Newcastle. At this time the only route from the west to Newcastle was via Sydney. The cross country line via Werriis Creek and Binna Way wasn't completed till April 1923.

According to the Bulletin magazine of the 1920's, which was a staunch critic of the Government, The Sandy Hollow to Mary Vale line would just be another branch line off other unplayable lines. On the way to Mary Vale, the line would cross two other unplayable lines, they being Wallerawang to Gwabegar and Orange to Dubbo lines.

|

| Proposed Mary Vale to Sandy Hollow line |

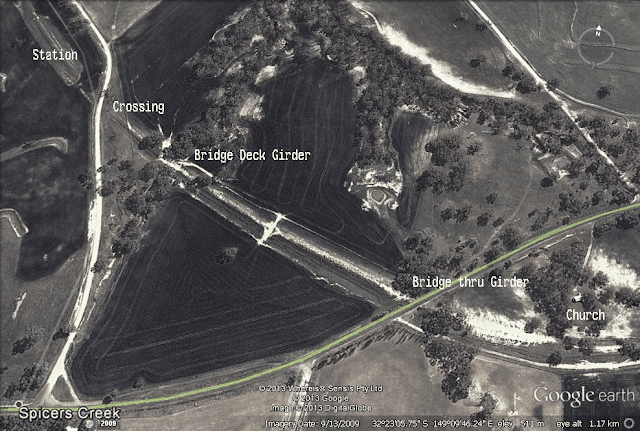

The NSW Public Works Commission agreed to the construction of the Sandy Hollow to Mary Vale line on the 7 January 1925. The length of the line would be 124 miles and cost around 1,172,895 pounds. On the 7 March 1927, assent was given to the Sandy Hollow to Mary Vale line via Gulgong Railway Act No: 28 of 1927. Land was acquired after the signing of the Act and before construction began. The plan for the Gulgong to Mary Vale section allowed for 5 stations and 1 tunnel.

The order from Golgong was:

Mebul Road, Goolma, Spicers Creek, Drill Creek and Comabella. The name of the triangular junction is thought to be and has appeared in publications as Mary Vale Junction. The station at Gulgong was already in existence on the Wallerawang to Gwabegar line.

* One tunnel would be required on the length of the line as well as 2 major bridges.

* The line was to be fenced fully and built for 60mph traffic,

* Gulgong was to have two triangles [wye] to allow traffic to flow to any direction out of the station.

* The line was to be fenced fully and built for 60mph traffic,

* Gulgong was to have two triangles [wye] to allow traffic to flow to any direction out of the station.

Work did not start until approved as an unemployment relief scheme and on the 21st February 1936, State Cabinet decided to proceed with the construction of the Sandy Hollow to Mary Vale line. The building costs permitted at this time were 1.353 million pounds but the actual expended to 1950 would be 2.43 million pounds. Construction commenced from Sandy Hollow heading West, Mary Vale heading East and Gulgong from both directions and involved about 500 men.

In 1936, the country as just coming out of the Great Depression and Europe was gaining a War footing. The newly authorized line was expected to immediately run at a loss and that was not really wished for at that time. The 1938 Annual Report of the Department of Railways stated the Muswellbrook to Sandy Hollow portion of the branch line should be strengthened to the same standards as the new line from Sandy Hollow to Mary Vale. The work between Muswellbrook and Sandy Hollow was completed by 1950. The cause of the 12 year delay in upgrading the Muswellbrook to Sandy Hollow portion of the line would have been attributed to the War and the fact that not much was constructed between Sandy Hollow and Mary Vale during the war years.

Work was steady until 1939 when World War II broke out and work was then confirmed to the tunnels and 3 major bridges, mainly due to a man power shortage. In 1941, the Commonwealth Government gave assistance in the form of 161,000 pounds to assist in early completion of the project as a special incentive. During 1942 and due to the war, the Government drastically cut back on funding for the line. By January 1942, work was again stopped except for concreting some tunnels. During the war years of 1941-42, the Sandy Hollow to Mary Vale line, earthworks still-uncompleted, was once again raised in State Parliament with reference to its link to the Port of Newcastle.

In 1946, work resumed again but due to a shortage of finances and steel, some bridges were not finished. In 1949, the last equipment was removed from the Sandy Hollow to Mary Vale project and taken to be used on the Branxton to Muswellbrook duplication. (Another railway project never finished) Work on the Sandy Hollow to Mary Vale line finally ceased around about 1950, At this stage, 85% of the work had been completed. It was estimated that on the 1st April 1964, the cost to finish the line would be $16,040,000 (taken from a report written in 1967 and expressed in decimal costs). At the end of 1965, although no work had been carried out in 16 years, the work completed included the following:

Some bridges are still there exactly as they were left during the 1950’s. e.g. Rush’s bridge (located on a property west of Beryl and owned by the Rush Family).

The platform faces and a goods loading bank at Comabella were completed and the platform at Gulgong was already in use.

Seventy five percent of the fencing along the line had been completed and all telegraph poles were in place.

Over culverts/flood openings varying in size from 2’x2’ to 10’x10’ had been completed also rabbit stops and cattle stops had been built. Road crossings had been formed and 95% of the right of way had been prepared.

The platform faces and a goods loading bank at Comabella were completed and the platform at Gulgong was already in use.

Seventy five percent of the fencing along the line had been completed and all telegraph poles were in place.

Over culverts/flood openings varying in size from 2’x2’ to 10’x10’ had been completed also rabbit stops and cattle stops had been built. Road crossings had been formed and 95% of the right of way had been prepared.

In 1969, the Development Corporation of NSW decided that it should not be completed. After another lapse of 10 years or so, in 1980, the Government announced the Sandy Hollow to Ulan portion of the line would be built with an agreement with Ulan Coal Ltd and White Industries. The line from Sandy Hollow to Ulan coal mine opened on 15 October 1982.

The Premier Neville Wran announced that the portion of the line from Ulan to Gulgong would be built after the Sandy Hollow to Ulan line was constructed and this portion opened on 16 June 1985.

Location Diagrams and Data:

Drill Creek will be modeled with all the features shown with the Station being a PC2 with platform mounted levers : refer Drill Creek article for more details.

Station will not be modeled : refer Spicers Creek article for more details.

Goolma will be modeled with all the features shown with the station being a PC3 with a separate signal box : refer Goolma article for more details.

Conclusion's

Conclusion's

We all have to thank other modelers who take the time to prepare these presentations and for preserving the information that they find - if you can go to a convention take the time to go and share with other modelers.

Thank you Chris Wangmann.

For those seeking a personal cost of the actual construction follow the link to the Dubbo PhotoNews - click here

For those seeking a personal cost of the actual construction follow the link to the Dubbo PhotoNews - click here