The key restriction to any O scale modeller are called curves, to turn through 180 degrees requires enough space for an N scale layout so there is a need to intensify the modelling and action under the mantra "Less can be much much more"

In practice, every element from the track up has to be distilled making it visually larger and this is what a steam generator provides visual intensity.

This idea was originally developed by TRS Trains in England and I would have a look at their Facebook site for more details. Smoke was one idea that I had originally used traditional smoke oil and I even have a number of generators that now will have to be assigned to the 40 class as the sole representative of the diesel class.

Smoke on the water is just that, oil smoke and it's known that prolonged use can coat models with an oily residue, I have had no proof but it was a concern. Oil smoke also has a heavy look but after reviewing the TRS product, water seems to address any issue of residue and the visual is nearly perfect with oil smoke consigned to diesel.

My first move was to purchase a moisturiser spray from eBay and disassemble it, what was found was it could be used by reorganizing to achieve the task. By nature and training, I am forced to create the best product that I can so after a period of design and parts research. A high-frequency oscillator and voltage regulator were selected to provide smoke and fixed voltage for fans controlled by the ESU decoder.

How to provide power for the oscillator was the next question as testing had shown that it drew 0.15 amps and you have to allow twice this for inrush. A decision was made to power it directly from the track requiring a separate 5VDC output with an AC/DC inverter to convert the DCC to DC. After testing a number of prototypes a single power box evolved as a means to marchell all the parts for assembly and prewired before integration with a decoder. An underlying reason was if powered from a decoder function it may/could create a heavy load on the stay alive and negate its value to the decoder.

This regulator could be replaced with resistors of the correct value but the power pack will not shrink due to the capacitor size, a smaller capacitor would help but I am not sure what the power would look like, so the decision was to play safe, in the name of success. In conclusion, a regulated power supply is stable regardless of track voltage so the value is one of balance.

"One flash it will be ash"

|

Oscillator Power Supply 50 wide x 46 long x 16 high |

In parallel to this, a means of storing water was developed combined with an oscillator head to mount the oscillator, two fans with one for chuff and the other for blowdown. Two 15 mm square computer fans were selected, sourced and check fitted onto a prototype head designed for this task. These fans are expensive at $US15 each but they were the smallest that could be found, how they will survive in a water stream will be a tale for another day.

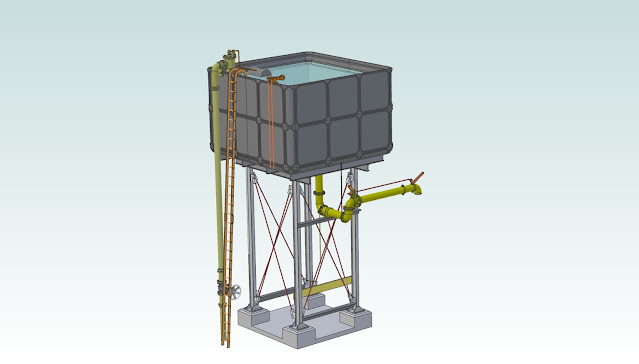

Pressure head is a function of height and in the desire to obtain the maximum time between fills required a large tank hence a custom one was designed but leakage was and still is an issue. Using a repetitive design process a 95%+ seal was achieved and any small weep that can/may occur will be controlled via a 3 mm drain hole through the base of the smokebox.

A lot of effort was required to achieve the minimum water usage and the tank and head that evolved created 60 minutes plus on the bench and has thus met my baseline to proceed.

|

Engine Head and Storage |

There is now a graveyard of ideas in the CAD system and on the bench but they evolved into the final package seen above.

In my first Vlog #1 a sound car installation was outlined and discussed in detail, at this time, there are 20 plus wagons ready for painting and decaling, so the ability to integrate the car sound [consist] with the locomotive was imperative for operation as envisaged.

Function Map

| Fwd/Rev, F0 | Front light [1]: Front Light | - | Dynamo | ||

| F1 | - | Dimmer | - | ||

| F2 | - | - | Whistle | ||

| F3 | - | Shift Mode 2 | Brake Engine | ||

| F4 | - | - | Brake Bail | ||

| Stop, F5 | Aux2 [2]: Blower Fan | - | Blower | ||

| Stop, F6 | - | - | Fireman | ||

| Stop, F7 | - | - | Guard | ||

| not F8 | Aux1 [1]: Fire Box | - | 2-8-0 GMR, Boiler | ||

| F9 | Aux6: Red, Front Rear | - | Dynamo | ||

| F10 | Aux7: White Front, Red Rear | - | Dynamo | ||

| F11 | Aux8: White Front | - | Dynamo | ||

| F12 | SoundCar Brakes on/off | Consist Mode | |||

| F13 | AUX9: Stay Alive on/off | - | - | ||

| F14 | - | - | - | ||

| F15 | - | - | - | ||

| F16 | - | - | - | ||

| F17 | - | - | - | ||

| F18 | - | - | - | ||

| F19 | - | - | - | ||

| F20 | - | - | - | ||

| - | - | - | - | ||

| Stop, F3, not F4 | - | - | Compressor Slow | ||

| Stop, not F3, F4 | Aux2 [2]: Fireman | - | Compressor Fast | ||

| - | - | - | - | ||

| F0r | Water Guage Light | - | - | ||

| - | - | - | - | ||

| - | - | - | - | ||

| Drive, F4, not F21 | - | - | Brakes Train | ||

| Drive, F4, not F22 | - | - | Wagons Clash | ||

| Drive, not F8, not F23 | AUX2 [1]: Chuff Fan | - | - | ||

| Stop, not F8, not F24 | - | - | - | ||

| Stop, not F8, not F25 | - | - | - | ||

| Stop, not F8, not F27 | - | - | Random Engine Operations | ||

| Stop, not F8, not F28 | - | - | Reverser Screw | ||

While not a complete picture, it does outline the thinking, any engineer will only need F1 to F7 to control the Engine/Train and use F9 to F11 for running lights and finally, F0 for the headlight. The bail or air transfer is assigned to F4, this transfers air brakes from the locomotive to the train and is used as a trigger [flag] for logic/lights/sounds associated with the train using F21 to F28 but requiring no operator input.

Aux 4 is assigned to a timer that operates a miniature relay to turn off the power to the generator to further save water and extent operational time while Aux 3 is assigned to the cylinder cocks and operates the blower for that application all with no operator input.

Aux 2 has a two-state function so when stopped [state 2] it operates the blower and when moving [state 1] operates the fan chuff and have independent function logic assigned to each output.

Function 8 [Sound On] is defaulted to on as per the Soundtraxx Tsunami to allow triggering of the SoundCar decoders to be consisted in and out of a train using the magnetic wand, F12 is reserved for this task.

This will all be covered in detail in a Vlog as sound is required to support this text once and if to all works - finally.