The Railway Crossing at Spicers Creek Road which would lead to the Station has two distinct concrete structures located at both sides. When these were first noted it was assumed that they were another culvert or cattle grid but at first inspection the construction showed no apparent exit in fact it formed a pit approximately 4 feet deep.

The explanation was to be reveled in a conversation with Chris Wangman at the Modelling the Railways of NSW Convention 2013. When these strange concrete pits were described to Chris explained that were a rabbit trap...!

This raised more questions than answers but there was now a new must model feature on the Spicers Creek models as it was intended to include the road crossing as a scenic feature. Following the introduction of myxomatosis to control rabbits in the 1950s, the importance of rabbit-proof fences and traps diminished.

|

| Pit at either side of road crossing - Spicers Creek |

|

| Stops and both flanks of pit |

|

| View at center |

The construction seems quite convoluted at first glance and no details seem to exist anywhere and most modelers have never heard of such a feature on NSWGR - the mystery deepened.

On a recent trip to gather more data and scenery materials time was taken to measure the pit for 3D modeling and manufacture.

|

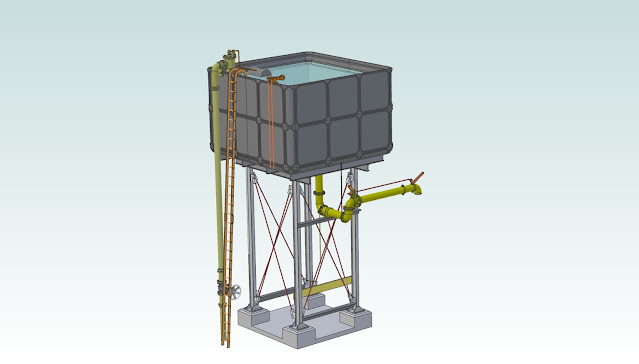

| Proposed Pit Design |

The 3D rendered model is a result of a best guess of the construction based on discussion within the group working on the module. We summarize that the 4 bolts were used to fix a 12'' x 8'' timber [refer Rabbit Trap Gangway] with the rail supported across the opening by a Universal Beam [U.B.] A 18'' deep beam fits between the underside of the rail. Standard NSWGR rabbit fencing would have been installed along the right of way and short wings installed on the road side to the rails for that purpose.

The use of the series of undercuts in the top side of the wall still made no structural sense until as a group the concept of a trap was full embraced.

|

| A rabbits road to destruction |

History

The question of the reasoning behind these installations is now history but was recently answered by Paul Baker from his conversation with old railway hand at the Arimdale Rail Museum. He explained that the farmer's were required to control rabbits on their property's by the Pastoral Protection Board but the NSWGR was exempt. In time the farmers prevailed on their property's so the rabbits moved to the railway right of way. Here they were safe as the farmer could not enter and the railway were not interested. Two events combined to create a sense of urgency for the NSWGR. The first was the rabbits began to borough in the road base which ultimately lead to collapses and secondly farmers decided to group together and to sue the railways for the damage from their rabbits on their land.

The NSWGR found the solution in the using a combination of rabbit proof fences and traps. This allowed the rabbits to be eradicated along the right of way by destroying their boroughs while the fences prevented escape onto the land at either side. The rabbit trap seal the end and provided the final point for extermination.

Rabbit trap or Modeling trap

In the illustration above shows two possible paths to destruction for rabbits. The trap is mirrored about the track center and repeated on the opposite side with the wall and cast in trenches forming a maize. Any rabbit approaching along the outside of the rail would come up against the 12'' high wall but is presented with a small drop and path down - this would match the rabbits natural instinct to enter borough so it follows the trench along the face of the wall to be presented with another small drop between the end of the wall and the face of the U.B. [not shown for clarity]. Again the rabbit follows the path that worked before and is now faced with a 40'' drop into a pit with no exit and as rabbit cannot turn or back up easily it is trapped with few options,

The center follows the same logic but is much shorter and direct but has the same result for the rabbit. The trenches also would have promoted water to fill the pit in wet periods further increasing deadly nature of the trap.

|

| Rabbit Stop at Yard exit -Spicers Creek |

This Rabbit Trap is found on the Spicers Creek side and marks the location of the Spicers Creek Station exit in an embankment. The rabbit trap shown above is located at the yard exit at Spicers Creek and are shown on the plans for the Spicers Creek Yard that Chris Wangmann has as part of his research on the line. The conclusions are supported by plans found for a shunters gangway for rabbits traps [NSWGR Plan #F1846] recently found by Ray Pilgrim and now in the data section of the blog.

|

| Culvert located between Spicers and Drill Creek |

This detail is the same as the rabbit trap design but without the wall and channel but suggests that the rabbit trap design is a modification of this standard culvert.